english

english

The Ball Eye, an integral power fitting, finds widespread application in electrical and power distribution systems. Its primary purpose is to establish a steadfast and trustworthy connection point for affixing conductors or cables to diverse equipment, including insulators or towers. It boasts a robust construction and employs durable materials, guaranteeing a stable and reliable connection even in challenging environmental conditions.

Ball Eye fittings are meticulously crafted using exceptionally robust materials that exhibit remarkable resistance to a multitude of environmental factors. These materials are carefully selected to withstand the rigors of diverse operating conditions, including adverse weather conditions, intense vibrations, and corrosive elements.

Thanks to their robust construction and exceptional resistance to environmental factors, ball eye fittings demand minimal maintenance. Regular inspections and minor adjustments are typically sufficient to uphold their enduring performance throughout their lifespan.

Ball Eye fittings prioritize safety as a paramount consideration in their design. Meticulously engineered, these fittings are purpose-built to provide a secure and steadfast grip on conductors or cables, effectively mitigating the potential hazards of conductor slippage or disconnections.

Ball eye fittings find extensive application across diverse power distribution systems, encompassing overhead transmission lines, substations, and distribution networks. Their versatility is a key attribute, rendering them suitable for deployment across various voltage levels and conductor types.

Ball eye fittings exhibit remarkable compatibility with an array of hardware and accessories employed in power line construction and maintenance. This inherent compatibility grants unparalleled flexibility in system design and expansion, rendering them highly adaptable for a wide spectrum of applications.

The ingeniously engineered design of ball eye fittings imparts exceptional mechanical stability to power lines, effectively preserving the desired tension and averting the risks associated with excessive sagging or loosening. This steadfast stability plays a pivotal role in ensuring the longevity and unwavering reliability of the power distribution system.

· Automotive Industry: for suspension systems, steering linkages, and control arms;

· Aerospace Industry: such as ailerons, rudders, and elevators;

· Robotics: in robotic systems, enabling smooth and precise movement in robot joints;

· Heavy Machinery: such as construction equipment and agricultural machinery;

· Medical Equipment: for articulation, rotation, and movement of various parts;

· Industrial Machinery: in various industrial machinery, including conveyor systems, material handling equipment, and assembly lines;

· Marine Industry: such as steering systems, winches, and booms;

· Energy Sector: in power transmission systems, wind turbines, and solar tracking systems.

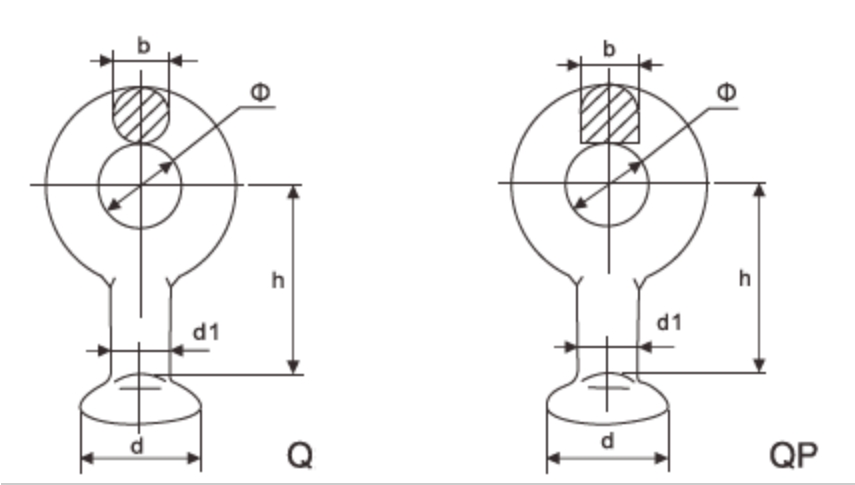

Type | Universal Type | Coupling Designated size | Dimension (mm) | Rated failure load(kN) | ||||

d1 | φ | b | d | h | ||||

Q-5 | - | 11 | 11.9 | 18 | 12 | 22.8 | 50 | 50 |

Q-7 | - | 16 | 17 | 22 | 16 | 33.3 | 50 | 70 |

Q-10 | - | 16 | 17 | 22 | 16 | 33.3 | 50 | 100 |

Q-12 | - | 16 | 17 | 24.5 | 16 | 33.3 | 53 | 120 |

QP-7 | QP-0750 | 16 | 17 | 22 | 16 | 33.3 | 50 | 70 |

QP-10 | QP-1050 | 16 | 17 | 22 | 16 | 33.3 | 50 | 100 |

QP-12 | QP-1260 | 16 | 17 | 24 | 16 | 33.3 | 60 | 120 |

QP-16 | QP-1660 | 20 | 21 | 26 | 20 | 41.0 | 60 | 160 |

QP-21 | - | 24 | 25 | 30 | 24 | 49.0 | 80 | 210 |

QP-21D | - | 20 | 21 | 29 | 21 | 41.0 | 70 | 210 |

QP-21S | QP-2180 | 20 | 21 | 26 | 20 | 41.0 | 80 | 210 |

QP-25S | QP-2580 | 24 | 25 | 30 | 24 | 49.0 | 80 | 250 |

QP-30 | - | 24 | 25 | 39 | 28 | 49.0 | 80 | 300 |

- | QP-3280 | 24 | 33 | 30 | 24 | 49.0 | 80 | 320 |

QP-3224G | - | 24 | 25 | 33 | 28 | 49.0 | 80 | 320 |

QP-4228G | - | 28 | 29 | 39 | 32 | 57.0 | 100 | 420 |

- | QP-42100 | 28 | 29 | 39 | 32 | 57.0 | 100 | 420 |

QP-5532G | - | 32 | 33 | 45 | 34 | 65.0 | 110 | 550 |

- | QP-55110 | 32 | 33 | 39 | 32 | 65.0 | 110 | 550 |