english

english

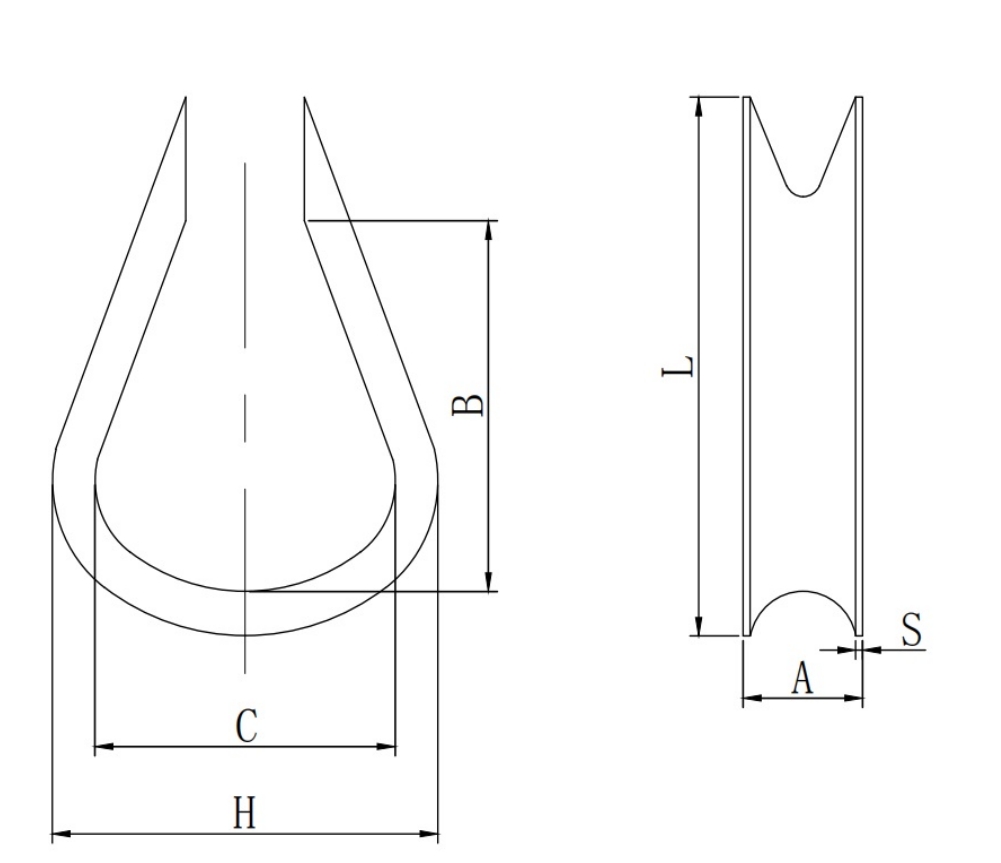

Definition of a Wire Rope Thimble A wire rope thimble is a teardrop-shaped piece of metal used to maintain the shape and integrity of the eye at the end of a wire rope. Wire rope thimbles protect against crushing forces and ensure that the eye maintains the proper diameter. Thimbles are used to protect the eyes of cables and wire rope slings from abrasion by providing a strong steel barrier between the fragile strands of cable and other rigging fittings used in the connection. Thimbles also prevent the eye from becoming deformed or twisted by providing structure to the wire rope eye. After repeated heavy-duty use, wear and kinks can reduce the strength of the cable and lead to premature failure. Starting with the most corrosion-resistant, stainless steel thimbles are best suited for outdoor use and are highly resistant to rust. Stainless steel thimbles are also ideal for use in or near marine environments where corrosion is common and are the best choice when using stainless steel cable or chain.

A rope thimble is a teardrop-shaped piece of metal used to maintain the shape and integrity of the eye at the end of a rope. Wire rope thimbles provide protection against crushing forces and ensure that the eye maintains the proper diameter.

Thimbles are used to protect cable eyes and wire rope slings from abrasion by providing a strong steel barrier between fragile rope strands and other rigging fittings used in the connection. Thimbles also prevent the eye from becoming deformed or twisted by providing structure to the wire rope eye. After repeated use under high loads, wear and kinks can reduce the strength of the cable and lead to premature failure.

Stainless steel thimbles, starting with the most corrosion-resistant, are best suited for outdoor use and are highly resistant to rust. Stainless steel thimbles are also ideal for use in or near marine environments where corrosion is common and are the best choice when using stainless steel cable or chain.

Types of Rope Thimbles

1. Lightweight sleeves are typically used in static applications such as permanent installation, controlled environment, or in situations where they will not be subject to heavy loads.

2. Lightweight thimbles tend to work best with traditional fiber ropes because they can withstand the same amount of stress and abuse as regular fiber ropes. Here you can see that this lightweight thimble is perfect for this application, while this heavyweight thimble is too large.

3. Heavy duty thimbles have extended protective material around the edges and a tendency to resist deformation in uncontrolled applications, they are typically used in applications that will experience dynamic loading or loads at or near the working load limit. Heavy duty thimbles are ideal for lifting, hauling and applications that require the user to frequently connect and disconnect the thimble to other rigging components.

How to use a rope thimble?

Wire rope thimbles are used with the cable and rope to provide eye protection and allow the rope to be routed smoothly around natural curves. So the most important thing is to make sure the eye of the thimble is secure. Here are some tips for using a wire rope thimble correctly: To determine the correct size wire rope thimble in relation to the cable, for example, when using 1/2 inch bare rope, use a 1/2 inch wire rope thimble. Make sure the cable lugs are the correct size and are securely fastened in the loop, not too loose or too tight, so that they can provide an additional layer of support for connecting to other rigging hardware of the same size.

| B (mm) | C (mm) | HOUR (mm) | S (mm) | L (mm) | Weight (kg) |

2 | 14 | 7 | 11.5 | 0.8 | 20 | 0,001 |

3 | 16 | 10 | 16 | 0.8 | 23 | 0.002 |

4 | 18 | 11 | 17 | 1 | 25 | 0.003 |

5 | 22 | 12.5 | 20 | 1 | 32 | 0,005 |

6 | 25 | 14 | 22 | 1 | 37 | 0,007 |

8 | 34 | 18 | 29 | 1.5 | 48 | 0,017 |

10 | 43 | 24 | 37 | 1.5 | 56 | 0.026 |

12 | 48 | +27.5 | 42 | 1.5 | 67 | 0,040 |

14 | 50 | 33 | 50 | 2 | 72 | 0,060 |

16 | 64 | 38 | 55 | 2 | 85 | 0,079 |

18 | 68 | 41 | 61 | 2.5 | 93 | 0.124 |

20 | 72 | 43 | 65 | 2.5 | 93 | 0.124 |

22 | 77 | 43 | 67 | 2.5 | 106 | 0.172 |

24 | 77 | 49 | 73 | 2.5 | 110 | 0.198 |

32 | 94 | 62 | 90 | 3 | 134 | 0.370 |

Application:

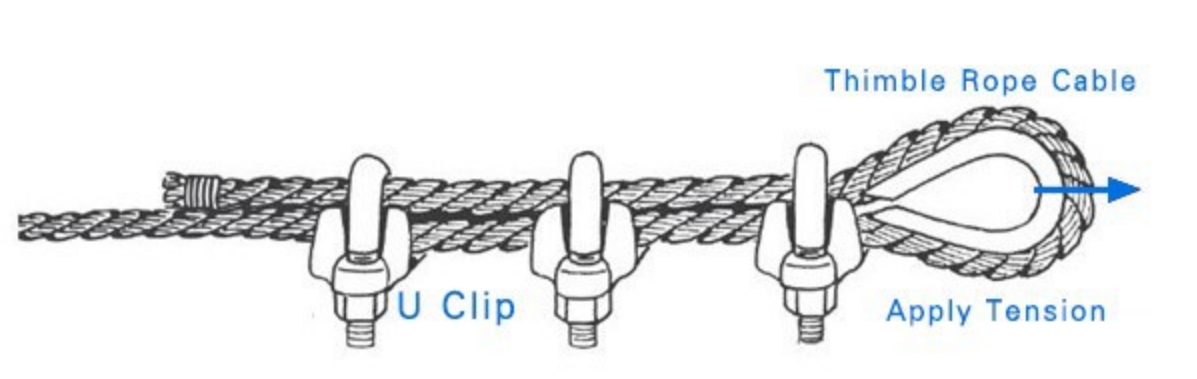

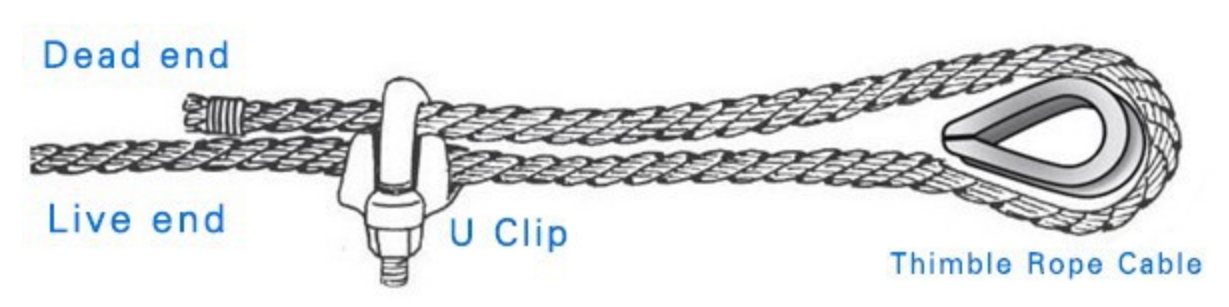

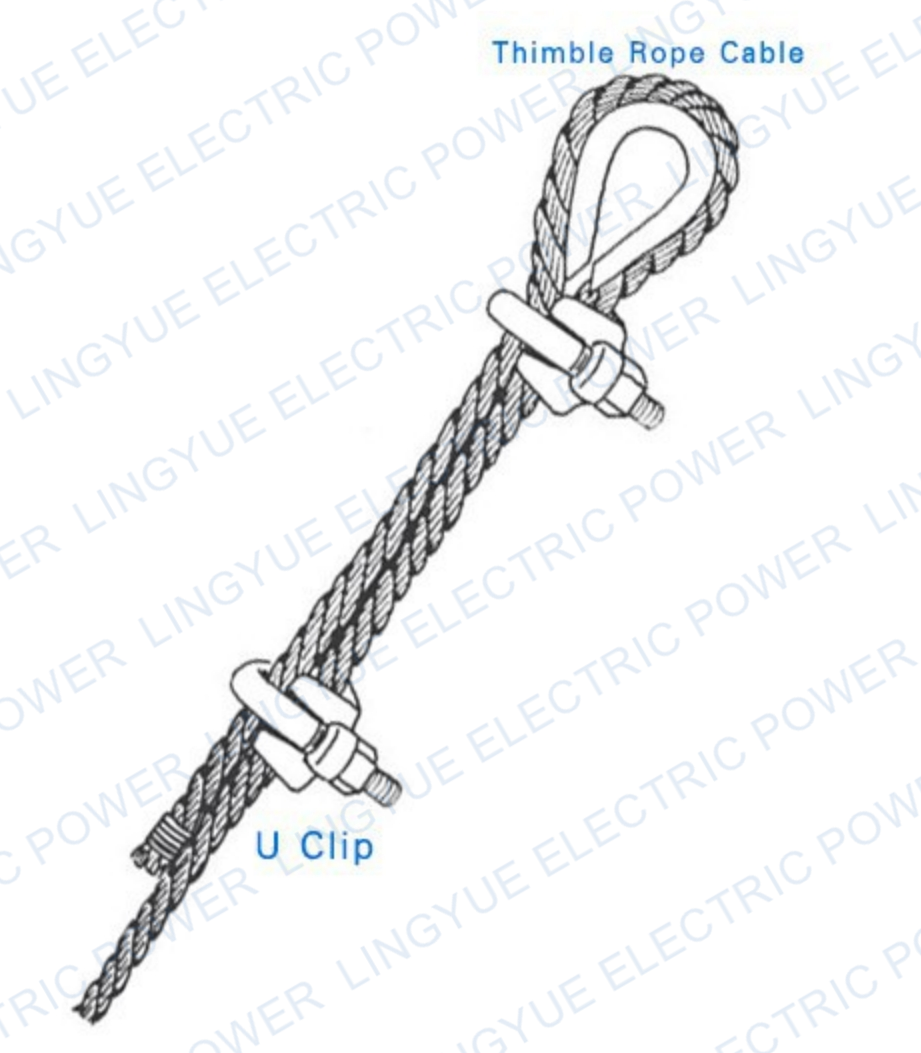

Step 1

Simply wrap the end of the rope around the outer groove of the thimble, tie the dead end of the rope to the U-bolt of the rope grips or the crimp end of the rope to secure it to the bearing mounting point at the end of the thimble to prevent wear caused by friction.

Step 2

Once in place, place another rope clamp next to the loop you just wrapped around the thimble. Tighten the nuts securely, but do not tighten them to the correct torque yet. We recommend using a crimping/crimping tool to press the tip firmly onto the rope to hold the thimble loop securely.

Step 3

Place all remaining rope clamps at the same distance between the first two and tighten them securely with an adjustable wrench to the recommended tightening torque. The distance between them should be 6-7 rope diameters.