english

english

Turnbuckles are used to adjust the tension of ropes, cables, tie-downs, and other tensioning systems, as well as to tighten and loosen anchor points. Heavy rigging turnbuckles consist of two threaded bolts, each threaded into the ends of a metal frame. One side is left-hand threaded and the other is right-hand threaded, so riggers can twist the metal frame to tighten and loosen the threaded bolts. These threaded bolts come with a wide variety of end fittings and attachments, including jaws, eyes, forks, hooks, and more. All cable turnbuckles and turnbuckle hardware are UNC threaded, so you can swap out end fittings and housings as needed.

Product Description

Turnbuckles are used to adjust the tension of ropes, cables, tie-downs, and other tensioning systems, as well as to tighten and loosen anchor points. Heavy rigging turnbuckles consist of two threaded bolts, each threaded into the ends of a metal frame. One side is left-hand threaded and the other is right-hand threaded, so riggers can twist the metal frame to tighten and loosen the threaded bolts. These threaded bolts come with a wide variety of end fittings and attachments, including jaws, eyes, forks, hooks, and more. All cable turnbuckles and turnbuckle hardware are UNC threaded, so you can swap out end fittings and housings as needed.

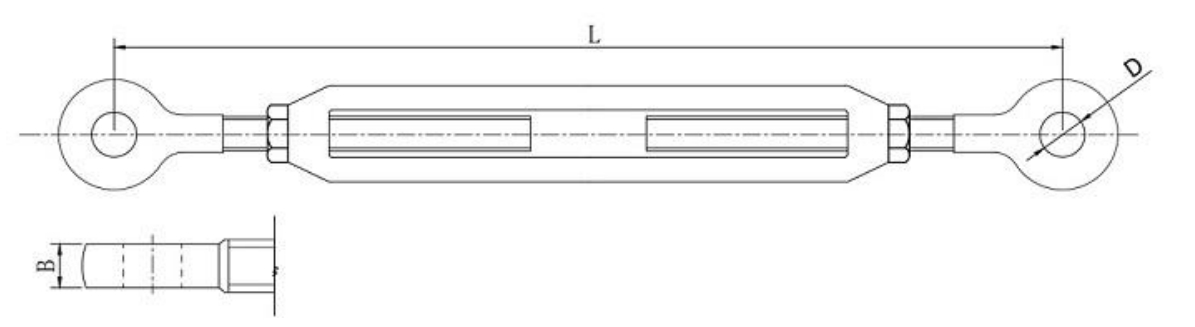

Turnbuckles are made up of a body and two end fittings. The inside length of the turnbuckle body determines the length that the end fittings can be screwed in and out. The dimensions are determined by the thread diameter of the end fittings and then the length that the end fittings can be screwed in and out (also known as the "pull"). So a ½" x 12" eye and jaw turnbuckle has end fittings with ½" diameter threads. The pull would be 12" and would have a jaw fitting on one end of the turnbuckle and an eye fitting on the other end.

Our heavy duty industrial turnbuckles are always made from one of the following materials:

* hot rolled steel

* galvanized steel

* stainless steel

* brass

* aluminum

Turnbuckles are very popular in the marine rigging industry, where corrosion resistance is often a top priority. Stainless steel offers the highest corrosion resistance, but can be expensive. On the other hand, galvanized steel is more economical, but less corrosion resistant. Brass turnbuckles are an ideal solution for applications that require explosion and spark protection. Aluminum turnbuckles lead the industry in light weight and low cost construction. Our heavy duty stainless steel turnbuckles can also be equipped with a housing, called a tube, that covers the threads and body of the wire rope turnbuckle. This option, sometimes called a closed body turnbuckle, is very popular in the architectural industry, where cosmetics are a top priority.

Catalogue No. | Adjustment range L (Mm) | Dimensions (mm) | Nominal load at failure (KN) | Weight (kg) | |

IN | D | ||||

HL-072529 | 250-290 | 16 | 18 | 70 | 1.6 |

HL-073042 | 300-420 | 16 | 20 | 70 | 1.9 |

HL-073045 | 340-500 | 16 | 18 | 70 | 2.0 |

HL-073552 | 350-520 | 16 | 18 | 70 | 2.1 |

HL-074772 | 470-720 | 16 | 18 | 70 | 2.5 |

HL-075080 | 500-800 | 16 | 18 | 70 | 2.6 |

HL-075389 | 530-890 | 16 | 20 | 70 | 2.9 |

HL-075686 | 560-800 | 16 | 20 | 70 | 3.4 |

HL-076498 | 640-980 | 16 | 18 | 70 | 2.6 |

HL-102529 | 250-290 | 16 | 20 | 100 | 2.4 |

HL-103650 | 360-500 | 16 | 20 | 100 | 3.5 |

HL-104565 | 450-650 | 16 | 20 | 100 | 3.5 |

HL-104772 | 470-720 | 16 | 20 | 100 | 4.0 |

HL-105389 | 530-890 | 18 | 20 | 100 | 4.8 |

HL-105775 | 570-750 | 16 | 22 | 100 | 4.2 |

HL-106498 | 640-980 | 16 | 20 | 100 | 4.3 |

HL-126090 | 600-900 | 16 | 24 | 120 | 5.0 |

HL-205773 | 570-730 | 24 | 30 | 200 | 9.7 |