english

english

Line post insulators are a kind of rigid insulators composed of one or more insulating parts permanently glued to a metal base, sometimes with a cap, and can be rigidly mounted on a supporting structure with studs or one or more bolts mounted on a metal base. They are used for insulation and support of conductors in AC power lines in ordinary areas and medium and heavy pollution areas with a nominal voltage higher than 1000V, a frequency not greater than 100Hz, and an altitude not exceeding 1000m. The ambient temperature of the installation site is between -40℃ and +40℃.

Line (solid) post insulators can replace pin insulators. Pin insulators are type B insulators, which are prone to breakdown and damage during operation. Tempered glass insulators will break by themselves at this time, while porcelain insulators will not break by themselves. Therefore, the power industry has to spend a lot of manpower and material resources to conduct electrical inspections and preventive tests on porcelain insulators, which has certain shortcomings in terms of economic and safe power supply. Therefore, with the development of manufacturing technology, line (solid) post insulators have emerged. This type of insulator has a solid insulator and belongs to type A insulator. Therefore, there is no need to worry about breakdown inside the insulator during operation, which is a major advantage.

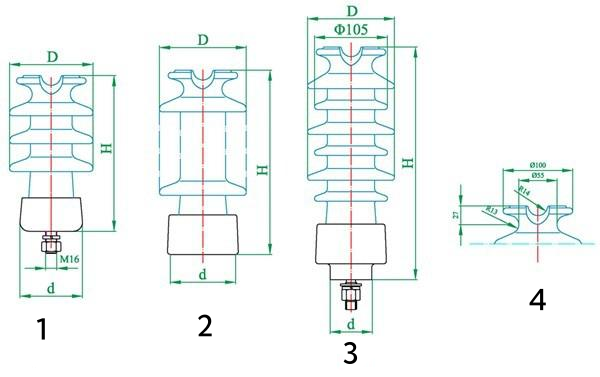

Line post porcelain insulators are divided into eight levels according to the rated lightning impulse withstand voltage value: 95, 105, 125, 150, 170, 200, 250 and 325kV; according to the rated bending failure load value, they are divided into four levels: 3, 5, 8 and 12.5kN; according to their installation method, they are divided into two types: upright installation and horizontal installation; according to their connection method with the high-voltage conductor, they are divided into two types: top binding type and top wire clamp type; according to the connection method between the steel foot and the base, they are divided into two types: detachable (threaded connection) and inseparable.

Insulator Model | Lightning full wave impulse withstand voltage(KV) | Power frequency wet withstand voltage(kv) | Mechanical bending failure load(KN) | Creepage distance(mm) | H (mm) | D (mm) | d (mm) | Head size standard drawing number | Center screw hole of base |

PS-200/12.5ZS | 200 | 85 | 12.5 | 620 | 430 | 180 | 120 | 4borc | M20 |

PS-250/12.5ZS | 250 | 95 | 12.5 | 860 | 510 | 190 | 120 | 4borc | M20 |

PS-325/12.5ZS | 325 | 140 | 12.5 | 1200 | 660 | 200 | 140 | 4borc | M24 |

PSN-95/12.5ZS | 95 | 38 | 12.5 | 350 | 222 | 165 | 100 | 4b | M20 |

PSN-125/12.5ZS | 125 | 50 | 12.5 | 530 | 305 | 170 | 100 | 4b | M20 |

PSN-170/12.5ZS | 170 | 70 | 12.5 | 720 | 370 | 180 | 100 | 4b | M20 |

PSN-200/12.5ZS | 200 | 85 | 12.5 | 900 | 430 | 190 | 120 | 4borc | M20 |

PSN/12.5ZS | 250 | 95 | 12.5 | 1140 | 510 | 200 | 120 | 4borc | M20 |

PSN-325/12.5ZS | 325 | 140 | 12.5 | 1450 | 660 | 210 | 140 | 4borc | M24 |