english

english

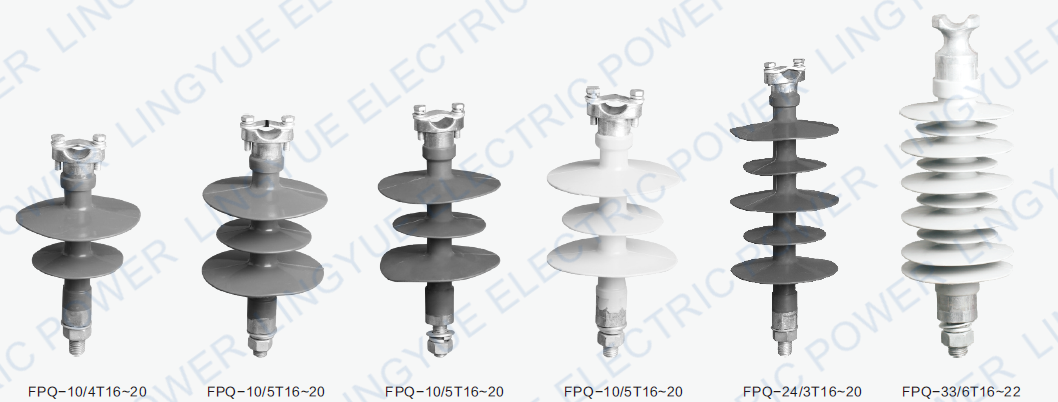

Composite pin insulator is made of glass fiber epoxy core rod, silicone rubber shed and metal fittings.

The silicone rubber shed adopt the whole packing pressure technique, and then to solve the key problem – interface electric spark puncture, which would affect the reliability of composite insulator.

The connection of the glass fiber rod and metal fittings adopts the pressure welding technique of the international advanced level and have the full automatic sound wave detection of defects system, high intension, beautiful outline, small volume, light weight, and the metal fitting of galvanization can corrosion prevention and exchange used with porcelain insulator.

This product is reliable structure, can’t damage the core rod, and take full advantage of the mechanical strength.

The dimension can be customized as per client’s requirement.

Material of end fittings: #45 forged steel, hot dip galvanized,thickness of the galvanization: ≥86μm

Material of the core: Epoxy & glass fiber (ECR type or FRP type).

Material of the weather sheds: HTV silicone, color grey

Product model | Nominal voltage (kV) | Nominal mechanical bending load (kN) | Construction height H. (mm) | Minimum Arc Distance (mm) | Minimum Creepage Distance (mm) | Shed diameter (mm) | Lightning impulse withstand voltage (peak value) (kV) | PF1min Wet withstand voltage (virtual value) (kV) |

FPQ-11/4 | 11 | 4 | 295 | 140 | 360 | 90/88 | 105 | 105 |

FPQ-11/5 | 11 | 5 | 280 | 180 | 380 | 90 | 105 | 105 |

FPQ-11/10 | 11 | 10 | 300 | 165 | 420 | 140/114 | 105 | 105 |

FPQ-11/12.5 | 11 | 12.5 | 320 | 195 | 450 | 110 | 95 | 95 |

FPQ-15/10 | 15 | 10 | 280 | 160 | 665 | 130/110 | 145 | 145 |

FPQ-24/8 | 24 | 8 | 315 | 200 | 450 | 120/100 | 145 | 145 |

FPQ-24/11 | 24 | 11 | 476 | 165 | 610 | 135/105 | 145 | 145 |

FPQ-33/8 | 33 | 8 | 425 | 320 | 1150 | 122/92 | 230 | 230 |

FPQ-33/10 | 33 | 10 | 406 | 280 | 940 | 122/92 | 200 | 200 |

FPQ-33/12 | 33 | 12 | 545 | 380 | 1485 | 200 | 250 | 250 |

FPQ-33/12.5 | 33 | 12.5 | 545 | 405 | +1650 | 150/120 | 265 | 265 |