english

english

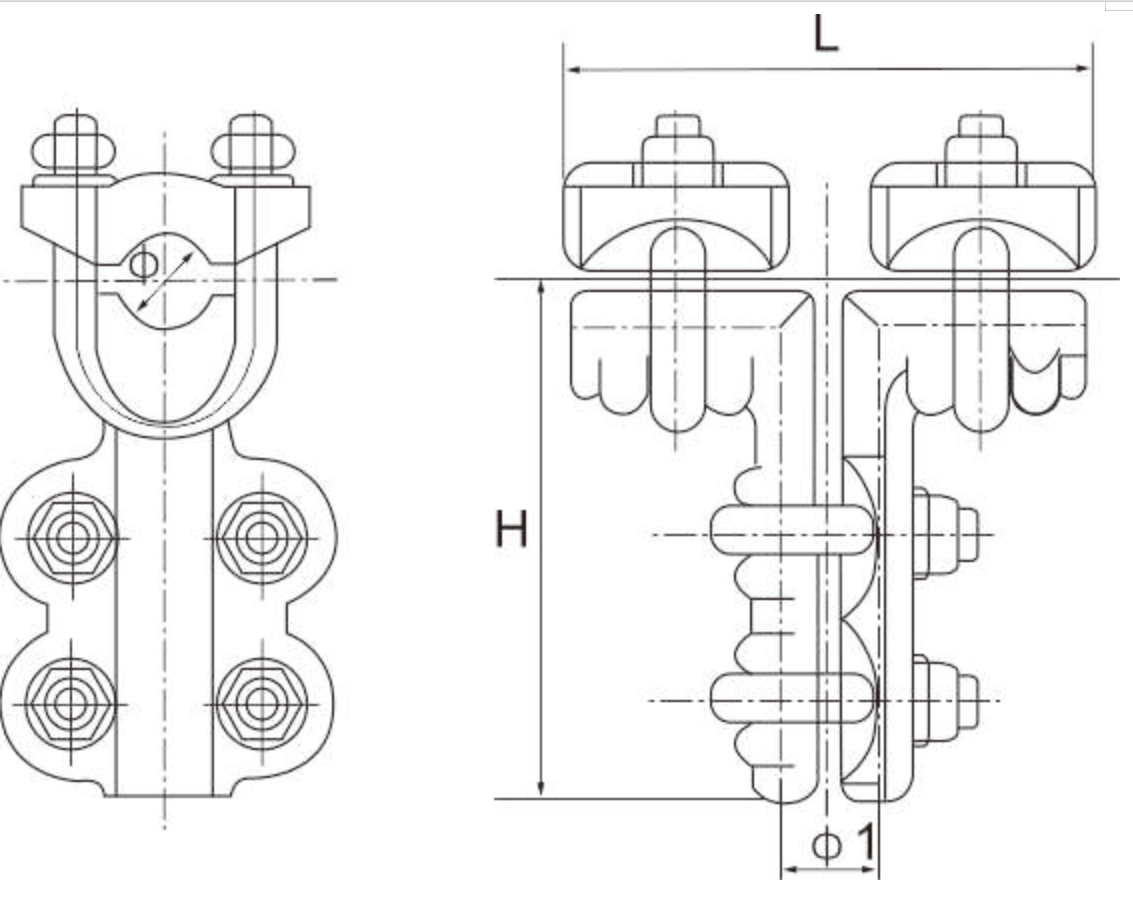

The T-type connector is suitable for overhead power line or branch connection of 10V insulation cable. It is composed of main body, gland, gland and bolts. The product series covers three types such as aluminum, copper, and copper-aluminum transition. The main body of copper and aluminum branch adopts flash welding technique, which has reliable and stable performance. The insulation cover will match the clamp for insulation and protection.

Description:

The T connector is suitable for the overhead power line or branch connection of 10V insulation cable. It is composed of main body, gland, gland and bolts. The product series covers three types such as aluminum, copper, and copper-aluminum transition. The main body of the copper and aluminum branch adopts the flash welding technique, which has reliable and stable performance. The insulation cover will match the clamp for insulation and protection.

Application:

The T connector is used in the main busbar or wire of other circuits, brings the main circuit to the electrical equipment, and connects the T connector at the intersection of two overhead power lines. In addition, it can be used in the T connection through the wedge connection or the compressed type. oval tube for small-section wires.

Advantages and disadvantages:

This T connection saves light and material, has good contact, and is convenient to install. However, after installation, it can not be removed, and it is suitable for the construction of new small and medium-sized substations. To improve the reliability of electrical contact, connect one, two or three parallel sets of groove clamps in series. The number of T-connectors will be added when using three parallel groove clamps or more to make a T-connection. The T-connector is expensive and has an unsightly appearance, it can only be used as a temporary replacement when there is no T-connection. Any type of T-connector must have sufficient contact pressure to obtain a stable contact. The oxidation films in the clamp groove should be seriously removed. and each bolt should be tightened uniformly.