english

english

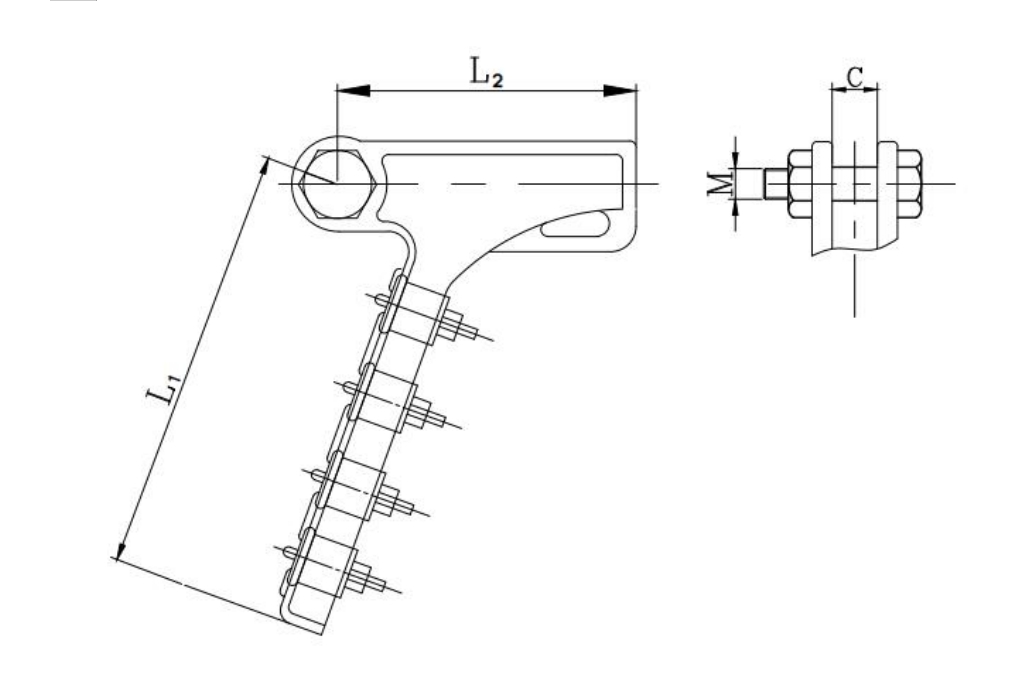

NLL series tension clamps are generally called bolted tension clamps or aluminum alloy tension clamps, which are used to fix aluminum wire or aluminum wire with steel core on the tension support, which are applied to overhead line below 220kV.

Description:

The tension clamp body is made of aluminum alloy, the other parts are hot-dip galvanized steel. The number of tension clamp bolts can be from one to five, depending on the tensile strength and conductors.

Application:

The tension clamp shall be able to withstand the full tension of the conductor or lightning rod, and the clamping strength of the clamp shall be not less than 90% of the rated tensile strength of the conductor or lightning rod to be installed, but it is not used as a conductor. This type of wire clamp can be removed after the wire is installed and used separately.

Advantages:

1. Convenient installation: no need for special tools and wire cutting.

2. Gripping and breaking load: Increased because the bolt clamp body and wedge core are made of high strength aluminum alloy materials.

3. Features: With self-locking function to keep the wire tight, which improves the safety and reliability of the line and brings the advantage of repeated use after removal.

4. Significant effect: no cutting of wire leads to reduction of electrical contact point, low loss, energy saving of transmission line.

Catalog No. | Conductor diameter. (MM) | Dimensions (mm) | Nominal failure Load (kN) | Weight | |||

M | C | L1 | L2 | ||||

NLL-1 | 5.1-11.5 | 16 | 19 | 140 | 120 | 40 | 1.0 |

NLL-2 | 8.9-18.5 | 16 | 24 | 176 | 187 | 40 | 1.6 |

NLL-3 | 5.0-15.0 | 16 | 18 | 310 | 160 | 70 | 1.9 |

NLL-4 | 12.1-21.8 | 16 | 30 | 298 | 284 | 90 | 4.1 |

NLL-5 | 18.0-30.0 | 22 | 36 | 446 | 342 | 120 | 7.0 |

NLL-6 | 27.0-38.0 | 22 | 44 | 560 | 360 | 120 | 8.1 |

NLL-2A | 7.0-16.0 | 16 | 20 | 111 | 137 | 40 | 1.6 |

NLL-4A | 12.0-21.8 | 16 | 30 | 298 | 292 | 102 | 3.9 |

NLL-5A | 18.0-30.0 | 16 | 32 | 190 | 235 | 70 | 3.9 |

NLL-6A | 27.0-38.0 | 16 | 36 | 296 | 255 | 70 | 4.0 |